1. Purpose of computer experiment

Taking the paper of your 1# paper machine as the object, in order to reduce the sizing cost or improve the sizing effect, the machine test of our surface sizing agent cse-1605 (expressed in FT below) was carried out.

2. Conclusion

1) When our company's surface glue cse-1605 is used in your 1# paper machine for FT, under the same coating process conditions and the same sizing degree, the addition amount fluctuates at 1.3 ~ 1.4kg/t paper. Compared with the current surface glue, the addition amount per ton of paper decreases by about 10%.

2) During the whole ft period, the sizing effect of the finished paper was stable without defective products; The foam in the sizing tank is good and has a downward trend. The paper machine is in stable condition and there is no paper break caused by poor sizing.

In conclusion, the machine test has achieved the expected purpose. We hope your company can conduct a medium and long-term test in the future to confirm the use effect of the product.

3. Ft related conditions of surface sizing agent cse-1605

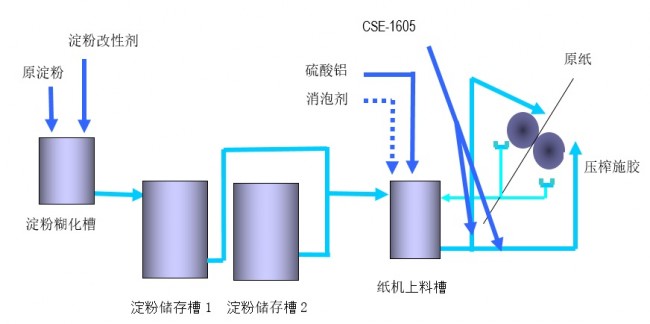

3-1) 1# paper machine manufacturing process and chemical addition conditions

Paper type: box board paper, quantitative 110g / m2

Starch type: corn starch, enzyme modified

Starch sizing amount: About 50kg / t paper

Coating temperature: about 70 ℃

Moisture control: about 8%

Vehicle speed: 590m / min

Daily output: About 400t / day under normal conditions

Aluminum sulfate addition: 6 ~ 7kg / t paper

Ft of our company's surface sizing agent cse-1605 is added from about 10:00 on August 22. In order to ensure product quality, the initial surface sizing flow is 29L / h (average 1.55kg per ton of paper, hourly output is calculated as 18.7t of paper, the same below). After the water absorption value is stable, the addition amount of surface glue is gradually reduced, the minimum is about 1.3kg/t paper (flow: 24 L / h), and the rewinding sizing degree is basically below 50. However, the off machine sizing degree has increased. For the sake of product stability, the dosage has increased, and the addition amount of surface glue cse-1605 of our company has always been maintained below 1.4kg/t paper in the experiments in the following days. The experiment ended on August 25.

3-3) result analysis

1) At present, the surface sizing agent used by your company in 1# paper machine is used for sizing. The addition amount is between 1.5 ~ 1.6kg/t paper, and the sizing degree of rewinding front and back for 2min basically fluctuates between 35 ~ 50 g / m2.

2) After the system sizing agent is switched from the current surface sizing agent to our company's surface sizing agent cse-1605, under the same coating process conditions, the addition amount of ton paper of cse-1605 can be reduced to 1.3 ~ 1.4 kg / t paper after adjustment, and the sizing degree of rewinding front and back sides is basically the same as that when using the current surface sizing agent.

Thank you very much for giving us this opportunity to carry out the computer experiment. We deeply apologize for the inconvenience caused to your company during the FT process!

Attachment 1: adding position of each sample at ft